As a packaging professional in the healthcare industry, it’s important to understand the basics of adhesive coatings, including why they’re important, and their impact on packaging materials. A better understanding of adhesive coatings will help you design and troubleshoot your sterile barrier system.

Pouches (Coated vs. Uncoated)

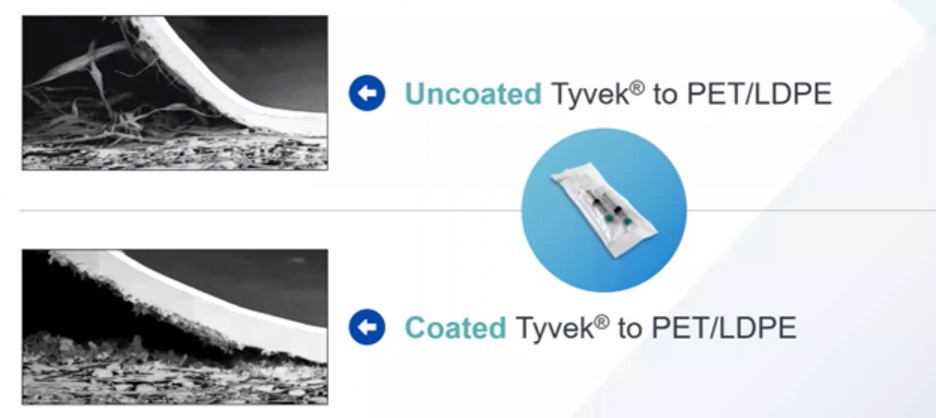

There are tradeoffs when using coated and uncoated materials for pouches. Some pouch applications lend themselves to using uncoated substrates more than others. Small or moderately sized pouches commonly use uncoated substrates.

However, long or narrow catheter device types may be better suited for coated substrates. Using a coated substrate on a long pouch can mitigate risks of materials tearing or fiber pick-off during the long peel down. Coating tends to be more forgiving, which is why it is more frequently recommended for these types of applications.

Applications

There are primarily three different types of platforms that cover the vast majority of applications that would use coatings. These three are pouches, lids/trays, and Thermoform Form Fill Seal (TFFS).

Pouches – May or may not employ a coated substrate and are generally premade by a converter or supplier. It is then up to the medical device manufacturer (MDM) to place the device inside and do the final seal.

Lids/Trays – The lids that are sealed to thermoform trays typically use a heat seal coating.

TFFS – Materials are supplied in roll stock format and formed in line. The top web is often a coated Tyvek or coated paper.

Adhesion vs. Cohesion

When formulating coatings, our scientists consider theories of adhesion and cohesion.

Adhesion – we formulate coatings that adhere to a wide variety of substrates used for sterile barrier packaging (Tyvek, Polyethylene, Polystyrene, Polypropylene, etc.).

Cohesion – we formulate the majority of our coatings to result in a cohesive peel. The coating splits when peeled and there is coating remaining on both substrates.

In the majority of sterile barrier applications, a cohesive peel is what formulators are striving for. A cohesive peel provides excellent visual evidence of a seal. Peel strength is controlled by the cohesive strength of the adhesive. The coating should split cohesively. In a tray and lid example, this would mean a portion of the coating stays on the Tyvek and another portion stays on the tray.

It’s important to know that not all coatings are created equal, and differences in formulations can impact risk. To learn more about adhesive coatings, check out this recent webinar that Sarah Webber, University of Wisconsin—Stout Packaging Engineering student, and I presented recently: HERE

The Fundamentals of Adhesive Coatings, written by Kevin Zacharias, Technical Director at Oliver, originally appeared on Oliver Healthcare Packaging’s Blog, PackTalk. Click here to subscribe.

Company Overview:

Oliver Healthcare Packaging Company is a leading supplier of sterile barrier packaging solutions. Oliver offers sterile-grade die-cut lid, roll stock, HDPE card, and pouch products to the medical device and pharmaceutical markets. Headquartered in Grand Rapids, MI, Oliver has manufacturing operations in Feasterville, PA; New Britain, PA; Hamilton, OH; Anaheim, CA; Venray, Netherlands; and Suzhou, China; and has sales offices and technical centers throughout the United States, Europe, China and Singapore. More information about Oliver is available at www.oliverhcp.com.

Contact information:

Caroline Streeter

Regional Manager

Cell: (616) 307-6073

cstreeter@oliverhcp.com